Proprietary technologies:

(1) Mine hoist automatic control technology

ENFI provides comprehensive hoisting system solutions for machinery, electrics, civil works and shaft construction, guaranteeing safe and efficient development of mine.

Since 1995, ENFI has completed more than a hundred EPC turnkey projects of hoist’s electric control. ENFI has good general contracting performance in copper, iron, vanadium-phosphorus, coal and other metal and nonmetal mines and masters invention patents in mine hoist automatic control technology.

(2) Paste filling automatic control technology

With mature paste filling process and rich engineering experience, ENFI develops an unique paste filling automatic control system by advanced distributed control system and practical instrument. The system controls the proportioning ratio of materials in the filling, paste pulp density and other important parameters, guaranteeing efficient and stable operation in paste filling process. The benefit is remarkable.

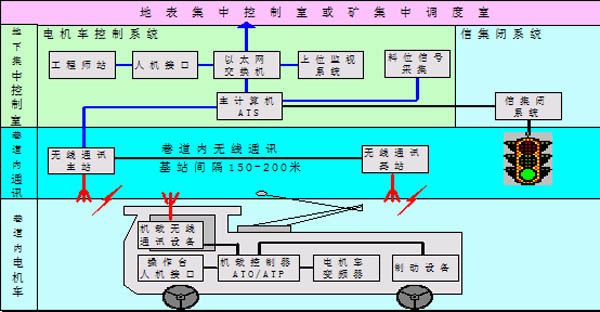

(3) Unmanned electric locomotive transportation technology

Unmanned electric locomotive transportation system sends the operating state of electric locomotive to ground control room by wireless communication; the computer control system in the control room allows operational control and real-time control for the electric locomotive. Electric locomotive positioning accuracy can be 1m. This system can significantly reduce the number of underground personnel, reduce the possibility of casualties, and avoid accidents caused by misoperation, overspeed derailing and fatigue driving etc., improve control efficiency and single transportation efficiency, and enhance the reliability of the transportation system.

This technology applies to the underground railway haulage of all non-coal mines, and is of great importance to the underground mining of special mines with water-rich, high rock burst and high altitude.

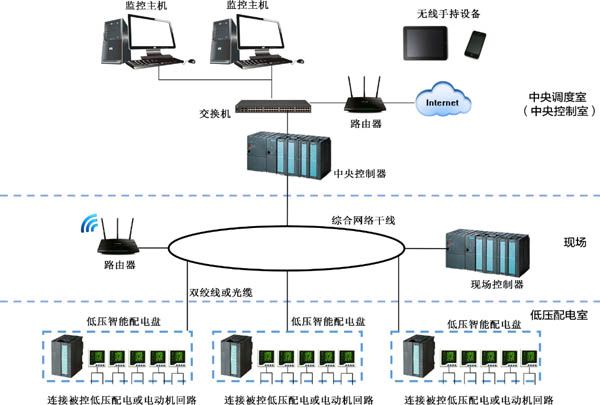

(4) Intelligent power distribution system

Intelligent low voltage power distribution system can monitor, collect and record the open-close state, voltage, current, power factor, kilowatt-hours, frequency and other parameters of the circuit in a real-time manner, and allow automatic prompting, alarming and tripping according to the set threshold value, thus protecting the distribution circuit, transformer and motor etc. Digital control is adopted for the whole system, which is characterized by high reliability, low cost, easy maintenance and expansion etc., and reaches unattended operation level.

The intelligent power distribution system developed by ENFI fully considers the demand of enterprise production for power distribution and control, realizes power distribution monitoring and logic control as one, simplifies the structure of the control system, improves enterprise automation level, and reduces the number of personnel on site; power supply and distribution data can be directly used by the control system and uploaded to the management and control system, thus providing a solid foundation for energy management and digital mining in power supply and distribution.

(5) Integrated mining information system

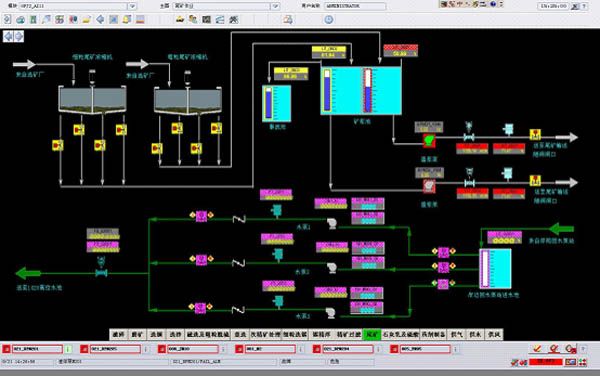

Main functions: the system monitors underground production operations of the whole mine in a real-time manner and controls the production in an unified way to realize efficient operation; allows video surveillance and automatic alarming for unattended sub-systems and remote control for equipment; records all production operation data, and generates production report and maintains data automatically; automatically saves the historical data for accident analysis and production optimization.

ENFI's advantages: ENFI has the capability and experience to realize automation of sub-systems; can keep close contact with mining and other disciplines and understand the whole demand of system; properly handles the connection problems with the whole mine system at each sub-system integration; considers comprehensive information system with simple and reliable network topology, few types of system equipment, few spare parts, small quantities of maintenance and few maintenance personnel.

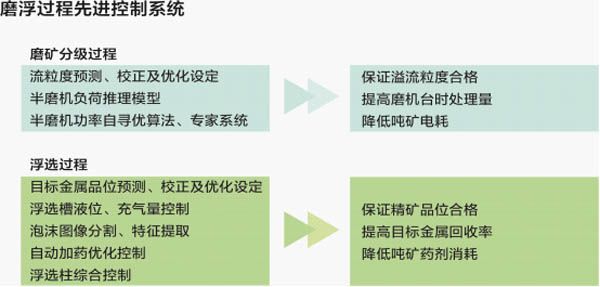

(6) Advanced control system for grinding and flotation process

(7) Six safety systems

(8) On-line safety monitoring system for tailings pond

Typical projects:

(1) Dongguashan copper mine of Tongling Nonferrous Metals Group

Dongguashan copper mine, located in the eastern suburb of Tongling City, Anhui Province, is the first large 1 km deep metal mine in China. The ore output of the mineral deposit is 10,000 t/d. The project was put into production in 2005.

This project is provided with 30t double skip hoist system with 4,400 kW AC synchronous motor; besides, concentrator automation, complete low pressure rock burst monitoring system, centralized control - multi-stage fan station variable-frequency regulating ventilation system are established, thus guaranteeing mine efficiency and safety.

In 2007, the intelligent expert control system for the filling process developed by ENFI was successfully applied at this mine. Good effects are achieved in the intelligent control of total tailings thickening and storage facilities, intelligent control of agitation tank level, intelligent control of water and materials feeding, on-line intelligent directing or adjustment of material ratio, etc. This system is characterized by good practicability, convenient operation and easy maintenance, and is praised by the owner.

In 2012, the unmanned electric locomotive transportation system for underground mines jointly developed by ENFI and Tongling Nonferrous Metals achieves success. It is the first unmanned electric locomotive transportation system in Asia.

(2) Dexing copper mine of Jiangxi Copper Corporation

Dexing copper mine, located in Dexing City, Jiangxi Province, is the largest open-pit copper mine in Asia. The comprehensive production capacity of mining and beneficiation is 130,000 t/d.

30,000t/d expansion project of Dashan concentrator designed by ENFI was completed at the end of 2010. Main beneficiation equipment of this project was the largest in China, including Φ10.37×5.19m semi-autogenous mill, Φ7.32×10.68m ball mill and 200m3 flotation machine. Its automation system upgrading was jointly completed by ENFI and Dexing copper mine using DeltaV control system of Emerson.

Dashan concentrator is also provided with particle size analyzer, current-carrying X fluorescence analyzer, froth image analyzer and other on-line analyzers. The modified Dashan concentrator maintains a model concentrator with the largest production capacity in Chinese metal mines and most advanced technologies.

(3) Bong iron ore mine reopening project in Liberia (1 million t/a iron concentrate)

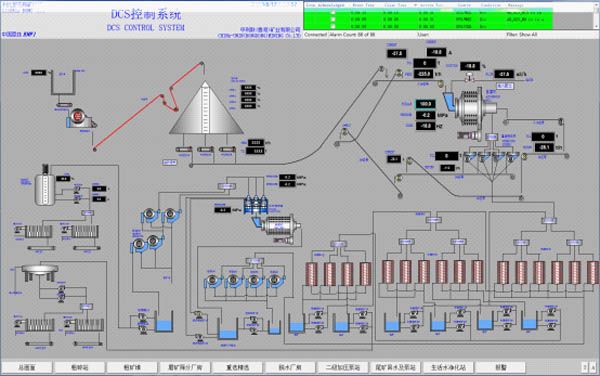

It is the first largest open-pit iron mining and beneficiation project completed and put into production in Africa by Chinese enterprise. The project consists of two phases. For Phase I project, the iron concentrate output is 1 million t/a, and mining - crushing - autogenous grinding (gravity separation) - ball milling (magnetic separation) process is adopted. ENFI undertook the design of the whole-plant automatic control system, integrated supply and commissioning. Distributed control system (DCS) is used and multiple control and detection strategies are used to realize SAG mill feeding and grinding density control, ball mill slurry density adjustment, and realize autogenous mill "belly" alarm by return underflow ratio calculation as well as real-time production monitoring and report database etc., thus improving the automatic production management of concentrator. The project was successfully put into production in August 2013.

(4) 8,000t/d concentrator expansion project of Yunnan Hualian Zinc & Indium Stock Co., Ltd.

The concentrator is arranged in single series. Advanced SAB process is used for grinding, flotation-magnetic separation - gravity separation process is used for separation, flotation is used for the recovery of copper, zinc and sulfur, magnetic separation is used for the recovery of iron, and flotation-gravity separation is used for the recovery of tin, thus realizing the comprehensive recovery of zinc, indium, tin, copper, silver, iron and sulfur.

ENFI undertook the design of the whole-plant automation control system, integrated supply and commissioning of equipment including field instrument, particle size analyzer, fluorescence analyzer, on-line tailings monitoring system and industrial television monitoring system. ENFI overcame the difficulties such as long process, complex engineering geology, large quantity of equipment, numerous and disorderly piping, and kept improving the control scheme during the supply of materials, system programming and configuration as well as commissioning of the project. The project was successfully put into production in September 2014 and highly recognized by the owner.